- Industrial

- Warehouse Curtains

- Separation Panels & Curtains

- Food Grade Curtains

- Welding Curtain Walls

- Auto Body Shop

- Paint Booth Curtains

- Aluminum Repair Curtains

- Photography Backdrop Curtains

- Commercial Barn Curtains

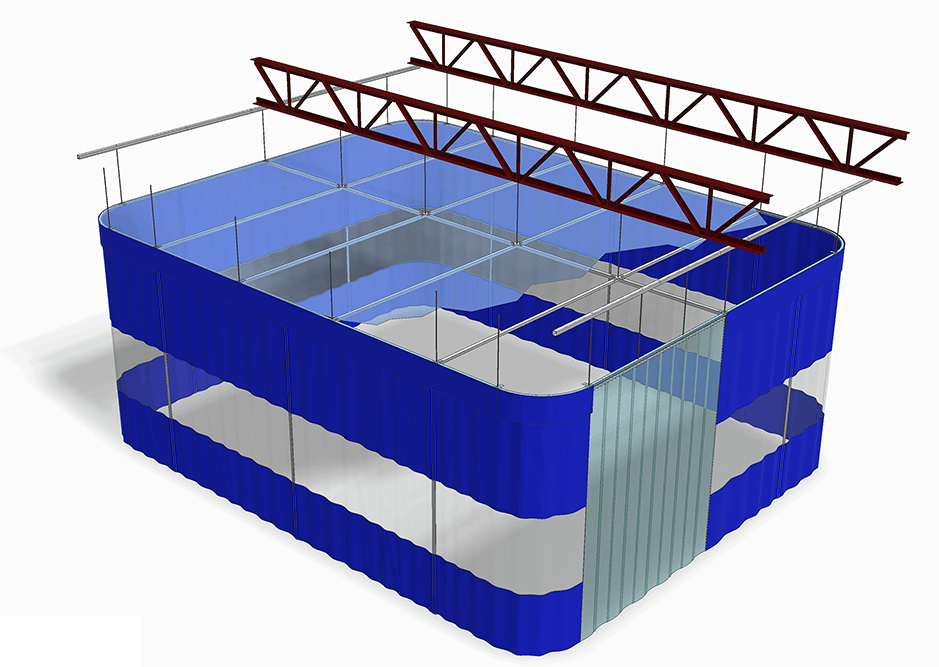

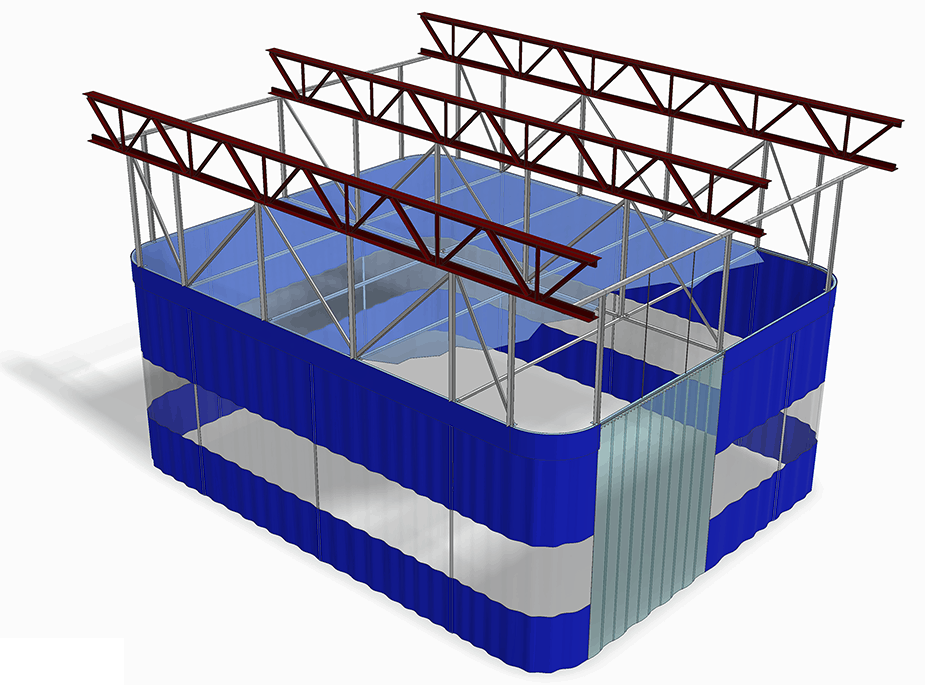

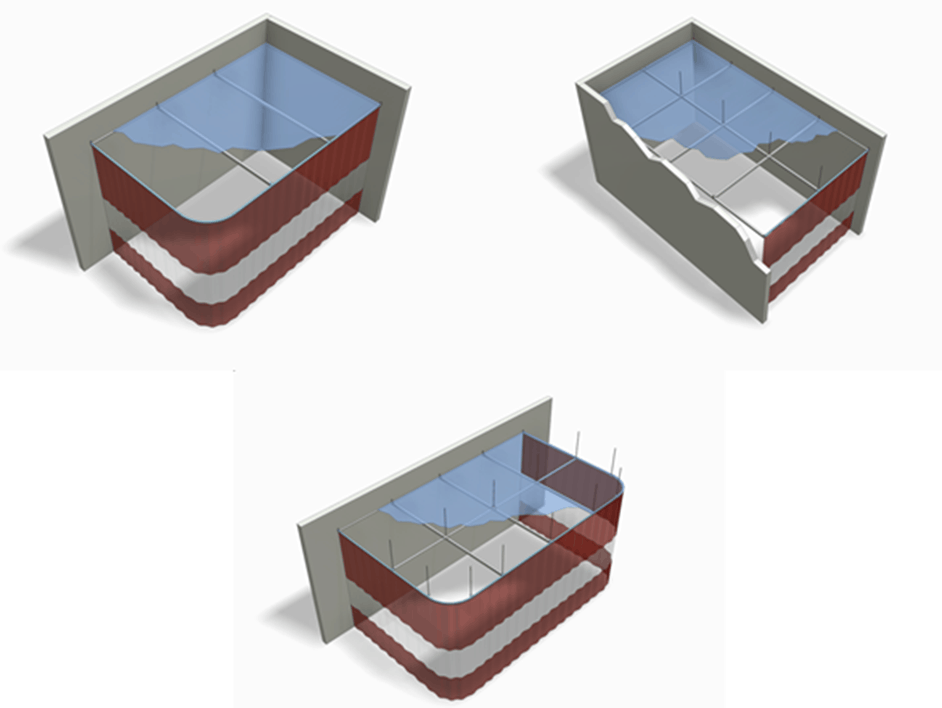

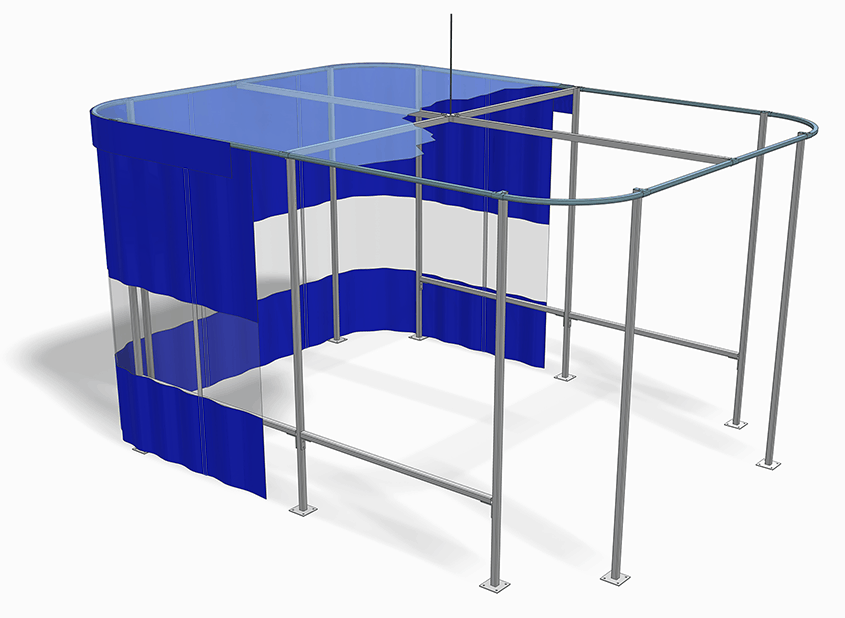

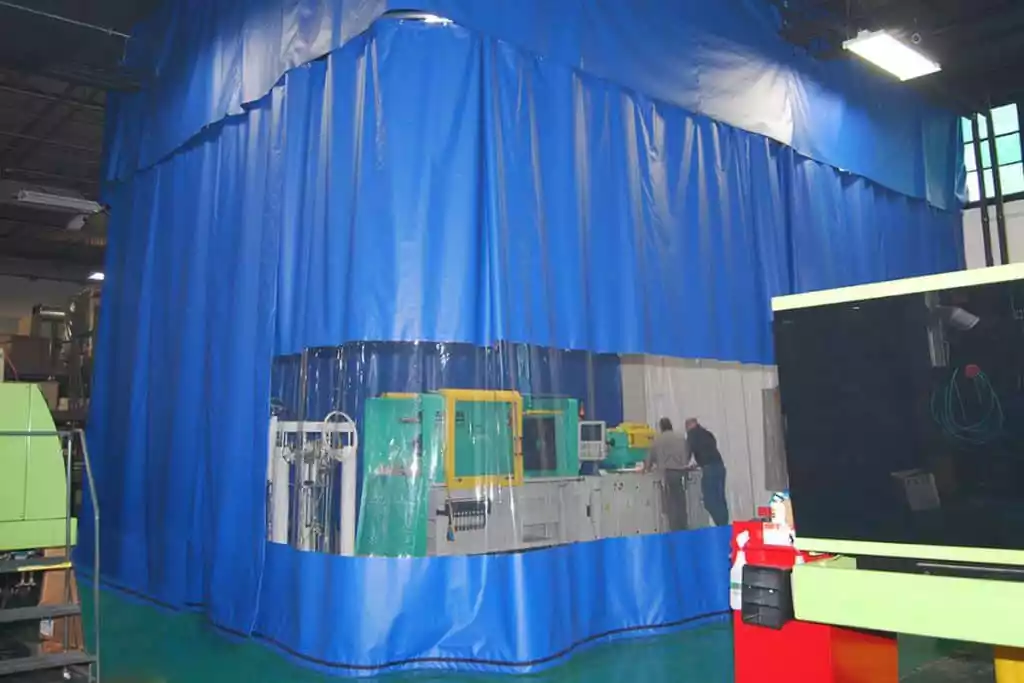

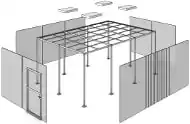

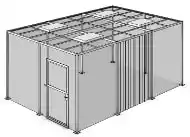

- Curtain Enclosures

- Anti-Static ESD Curtains

- PVC Strip Doors

- Heavy Duty Outdoor Curtains

- High Temperature Curtains

- Stock Industrial Curtains

- Custom Curtain Walls with Logos

- Data Center

- Thermal

- Acoustic

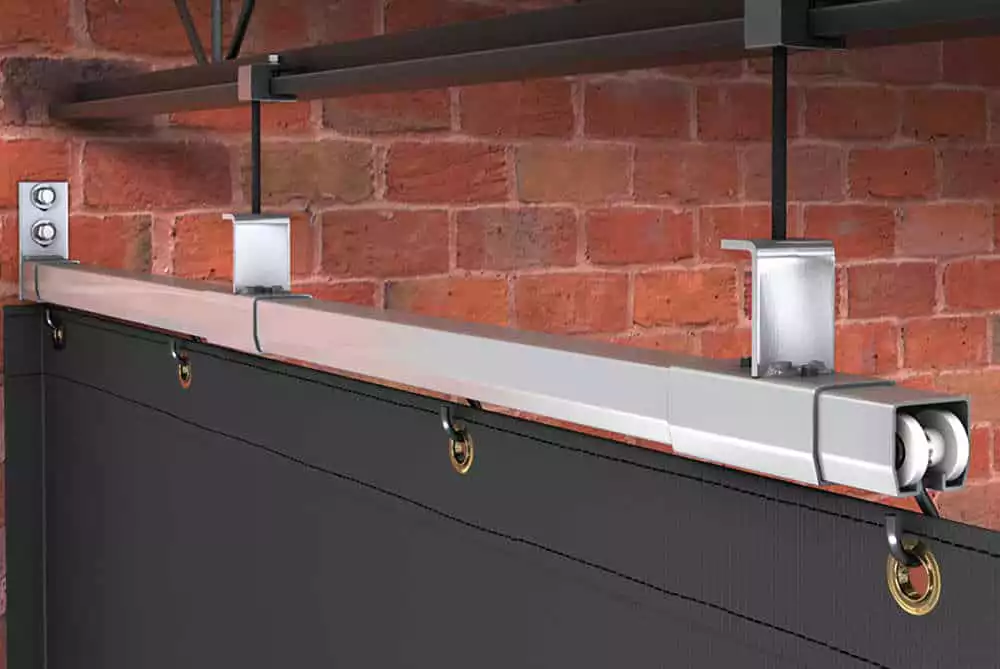

- Hardware

- Installation

- Product Showcase

- Resources

- Industrial

- Warehouse Curtains

- Separation Panels & Curtains

- Food Grade Curtains

- Welding Curtain Walls

- Auto Body Shop

- Paint Booth Curtains

- Aluminum Repair Curtains

- Photography Backdrop Curtains

- Commercial Barn Curtains

- Curtain Enclosures

- Anti-Static ESD Curtains

- PVC Strip Doors

- Heavy Duty Outdoor Curtains

- High Temperature Curtains

- Stock Industrial Curtains

- Custom Curtain Walls with Logos

- Data Center

- Thermal

- Acoustic

- Hardware

- Installation

- Product Showcase

- Resources